Whilst digital twins have been discussed and used widely in some industries, other sectors are slower in adopting them for numerous reasons. A digital twin is “a connected data representation of an entity, such as a physical asset, a process or system throughout its lifecycle.”

An important aspect to note is “throughout its lifecycle” — this is not a snapshot view of an asset at a point in time, but an up-to-date, “live” version of the real thing. This makes digital twins complex, but it also enables them to become digital realities.

Dynamically capturing data

Just capturing the data from a physical asset is insufficient; a mechanism for updating the data needs to be in place, and it needs to be achievable in practical terms. A new LiDAR scan of a frigate is not going to be done daily, but linking and reading data from real-time sensors will help keep the currency of the digital twin up to date. Doing so takes advantage of the benefits of the internet of military things to serve data to the digital twin.

What if the physical asset has non-digital sensors, though? What if a maintenance team needs to read analogue meters to gather the current status data for later input into the digital twin database? This may be unavoidable, if the meters and sensors on the physical asset cannot be replaced with digital versions.

Leveraging AI

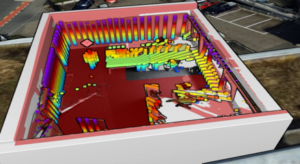

One way to capture this data and use the benefits of the digital workflow is via an optical camera with embedded artificial intelligence. We’re working with partners on this, as seen in the example below. When there are tens or hundreds of dials to read, having a speedy and accurate methodology is paramount.

Defence assets are wide-ranging, from rounds of ammunition to aircraft carriers. How to capture data on these in a digital format, whether via LiDAR scan, a design file, or simple location, is determined by the urgency of the need. Information about the asset can be shared based on the ease of creating a digital record of the asset.

For larger physical assets, scanning with LiDAR technology will generate a precise replica of the surface of that asset, be it a room, building, training camp or frigate. Hexagon offers various LiDAR scanning products, including the BLK series with autonomous mobile capture. The BLK2FLY is an autonomous flying laser scanner with advanced obstacle avoidance for easy reality capture from the sky. The Leica BLK ARC is an autonomous laser scanning module for robots. The BLK2GO is handheld, wireless and lightweight, designed for fast reality capture on the move.

Integration of real-time sensors that can feed a digital twin are well known and used in cases such as vehicle tracks. Today, these sensors can have onboard edge processing and send alerts to the digital twin, rather than all data, meaning only relevant information is transmitted. One such sensor is the BLK247, a combination of video cameras, thermal imaging, and LiDAR — along with edge computing and AI to instantly detect and report physical changes within a space.

Repetitive scanning of an asset, such as a room space or perimeter wall, means that changes can be quickly detected and flagged for attention in the digital twin. But once all this base data and real-time data is available, how can the digital reality, as it now is, be visualised?

Location intelligence

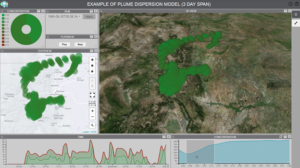

Graphical, geography-based views of the assets are one way to present the information and status to analysts and decision makers. As everything exists somewhere, using geography as the underpinning reference for the digital reality keeps everything in its place and allows for cross-referencing based on location; if asset A needs to be moved, what other assets will be affected?

If the assets are on a physical network, such as a water pipeline or fuel tank, then the digital version can be used for tracing impacted flows and calculating which valves need to be closed before any work is carried out. Also, an early Hexagon prototype showed how work permits can be visualised in three dimensions over time to look for conflicts that a normal job sheet will not show. This “view of the future” is a major benefit of a digital reality; predictive or modelled data can be visualised and analysed along with real-time data from the system.

Immersing military personnel intro training simulations is becoming common; so should immersion into a digital reality. As the technology behind AR (augmented reality) and VR (virtual reality) headsets has advanced, Hexagon has demonstrated some military use cases for them. Having multiple C2 displays within one headset allows a commander in the field, possibly literally, to see the same information as presented to the commanders in the HQ with multiple screens.

As with most datasets, digital realities need to be designed to be fit for purpose to deliver relevant information to the user group. How the information is visualised is important. Some users will need to know how many vehicles are in range of a fuel dump, whereas other users will just need to know which vehicles are nearing their scheduled maintenance checks. Relating the assets correctly to a reference system, such as Uniclass (recently adopted by the UK government), gives assurance as to which assets data represents and enables the sharing of data between digital twins.

Winning on the digital battlefield

As any modern conflict can only be won on the physical battlefield by dominating the digital battlefield, having an assured, secure, up-to-date digital reality is paramount for any commander. There are many moving components of this digital reality, and solution providers such Hexagon help defence organisations leverage and transform complex data into the timely, accurate and actionable information necessary for mission-critical decision-making across domains.

Learn more

For more information, check out a complete overview of digital solutions for defence, read more blog posts on defence and the digital battlefield, or contact us to discuss your digital reality requirements.